3003 is an AL-Mn alloy, which is a widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than that of industrial pure aluminum) and cannot be strengthened by heat treatment. Therefore, cold working methods are used to improve its mechanical properties: in The annealed state has high plasticity, good plasticity in semi-cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, and poor machinability. Mainly used for low-load parts that require high plasticity and good weldability, and work in liquid or gas media, such as fuel tanks, gasoline or lubricating oil conduits, various liquid containers and other small-load parts made by deep drawing: Wire is used to make rivets.

3003 aluminum plate has good formability, weldability and corrosion resistance. It is used for processing parts and components that require good formability, high corrosion resistance and good weldability, or work that requires both these properties and higher strength than 1XXX series alloys, such as kitchenware, food and chemical products handling and Storage devices, tanks and tanks for transporting liquid products, various pressure vessels and pipes processed with thin plates, general utensils, heat sinks, cosmetic plates, photocopier rollers, and ship materials.

Corrosion resistance: The corrosion resistance of 3003 aluminum alloy is very good, close to the corrosion resistance of industrial pure aluminum, and has good corrosion resistance to atmosphere, fresh water, sea water, food, organic acid, gasoline, neutral inorganic salt solution, etc. , the corrosion resistance in dilute acid is also very good.

Production Applications:

This product is often used in humid environments such as outer packaging, mechanical parts, refrigerators, air-conditioning ventilation ducts, etc. The product has good rust resistance.

3003 aluminum plate is often used in ships, ships, vehicle materials, automobile and aircraft plate welding parts, pressure vessels requiring strict fire protection, refrigeration equipment, TV towers, drilling equipment, transportation equipment, missile components, armor, etc.

Product Parameter

| Aluminium Alloy | Thickness (mm) | Width (mm) | Length (mm) | Temper |

| A1050,A1060,A1070,A1100 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H16,H18,H22,H24,H26 |

| A3003,A3004,A3105 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H16,H18,H22,H24,H26 |

| A5052,A5005,A5083,A5754 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H34,H32,H36,H111,H112 |

| A6061,A6082,A6063 | 0.15-200 | 20-2620 | 20-8000 | T4,T6,T651 |

| A8011 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H16,H18,H22,H24,H26 |

| Standard Width | 914mm,1000mm,1220mm,1250mm,1500mm | |||

| Material process | CC AND DC | |||

| Customerize size | Size can be produced as per clients requirement | |||

| Surface | Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing | |||

| Mirror,Brush,Perforated,Tread plate ,Corrugated etc | ||||

| Quality Standard | ASTM B209,EN573-1 | |||

| MOQ per size | 2 tons | |||

| Payment Terms | TT OR LC OR DP at sight | |||

| Delivery time | Within 25 days after receipt the lc or deposit | |||

| Material Quality | Tension levelled ,flat ,Free of defects like oil stain,Roll Marks,Waves,Dents | |||

| scratches etc ,A+++ quality, production process passed sgs and bv inspection | ||||

| Application | Construction ,Building,Decoration ,Curtain Wall ,Roofing,Mould,Lighting, | |||

| ship building,Aircraft,Oil Tank ,Truck Body etc | ||||

Products Application

1. Lighting lighting

2, solar reflector

3, architectural appearance

4, interior decoration: ceiling, wall, etc.

5, furniture, cabinets

6, the elevator

7. Signs, nameplates, cases and bags

8, car interior and exterior decoration

9. Interior decorations: such as photo frames

10, household appliances: refrigerator, microwave oven, audio equipment, etc.

11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites and other aspects.

12, mechanical parts processing

13, mold manufacturing

14, chemical/insulation pipeline coating.

15. High quality boar

Aluminum has a density of 2.7 which is about 1/3 that of copper (8.9) or steel (7.8). Low density is very beneficial for the lightweight of ships, vehicles, aerospace vehicles and other vehicles and buildings.

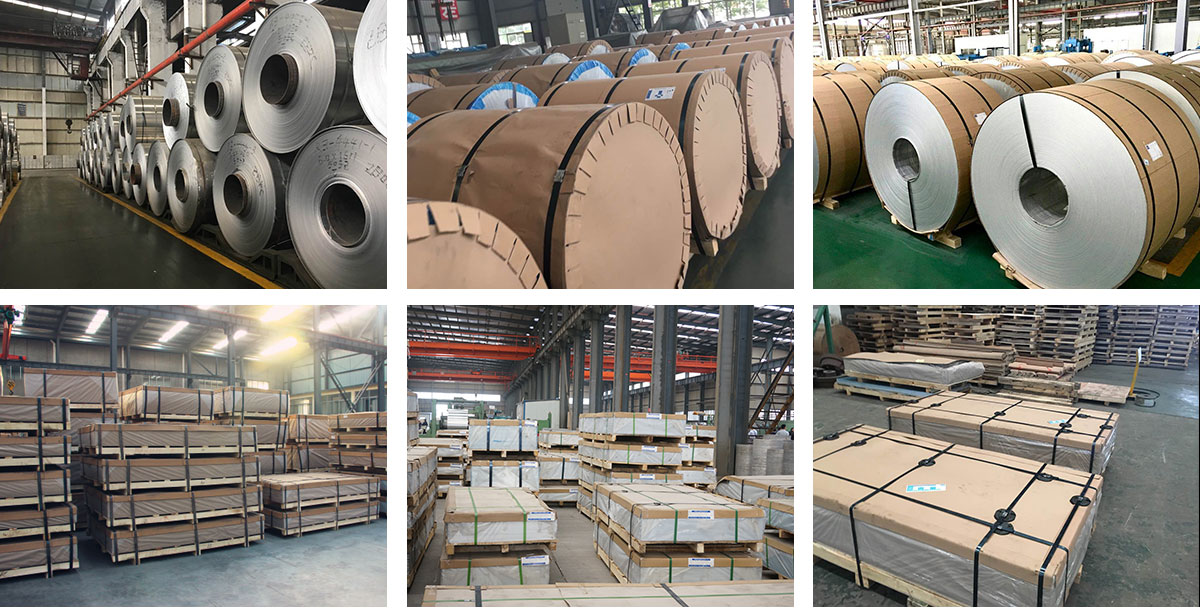

Our Advantage

1.PRODUCTION ADVANTAGES

Integrating steel sales, manufacturing, processing, distribution, and service.

Focused on the aluminum sheet/plate/coil industryfor many years.

Large warehouse supply with largequantity of goods and spot supply.

Various specifications support retaicutting processing customization.

2.DIVERSE EOUIPMENT

Strength certification is trustworthy

Good faith, large business volume, excellentprice.

Wide range of use, qualified product qualityinspection, safe and reliable use.

A COMPREHENSIVE SERVICE SYSTEMThe customer service team is attentive to serving you

Friendly service and timely after-sales service

Supply and delivery speed of goods.

10000 ton inventory quality assurance.

Quality Control

Factory Stocks

If you need our products please write down any questions, we will reply as soon as possible.